BIG CHEESE

By Monica Kass Rogers

WORDS & PHOTOGRAPHY BY MONICA KASS ROGERS

Nat Caputo

By Monica Kass Rogers

WORDS & PHOTOGRAPHY BY MONICA KASS ROGERS

Nat Caputo

The energy Natale “Nat” Caputo generates is infectious. Bright and quick, it lightens your step as you follow him through the vast maze of spaces that make up Caputo Cheese’s headquarters in Melrose Park.

For Caputo, each room is filled with story. He offers food techie tidbits here, fond childhood memories there. And always with the enthusiasm of someone who loves what he does.

CEO of Caputo Cheese since 1996, Caputo oversees output of 35 million pounds of cheeses each year. The bulk of that is hard cheese, such as Parmesan, Asiago, and Romano, but fresh mozzarella sales are growing.

“We do 100,000 pounds of fresh mozzarella per week, spiking to between 150,000 and 200,000 pounds during peak summer salad season,” he says.

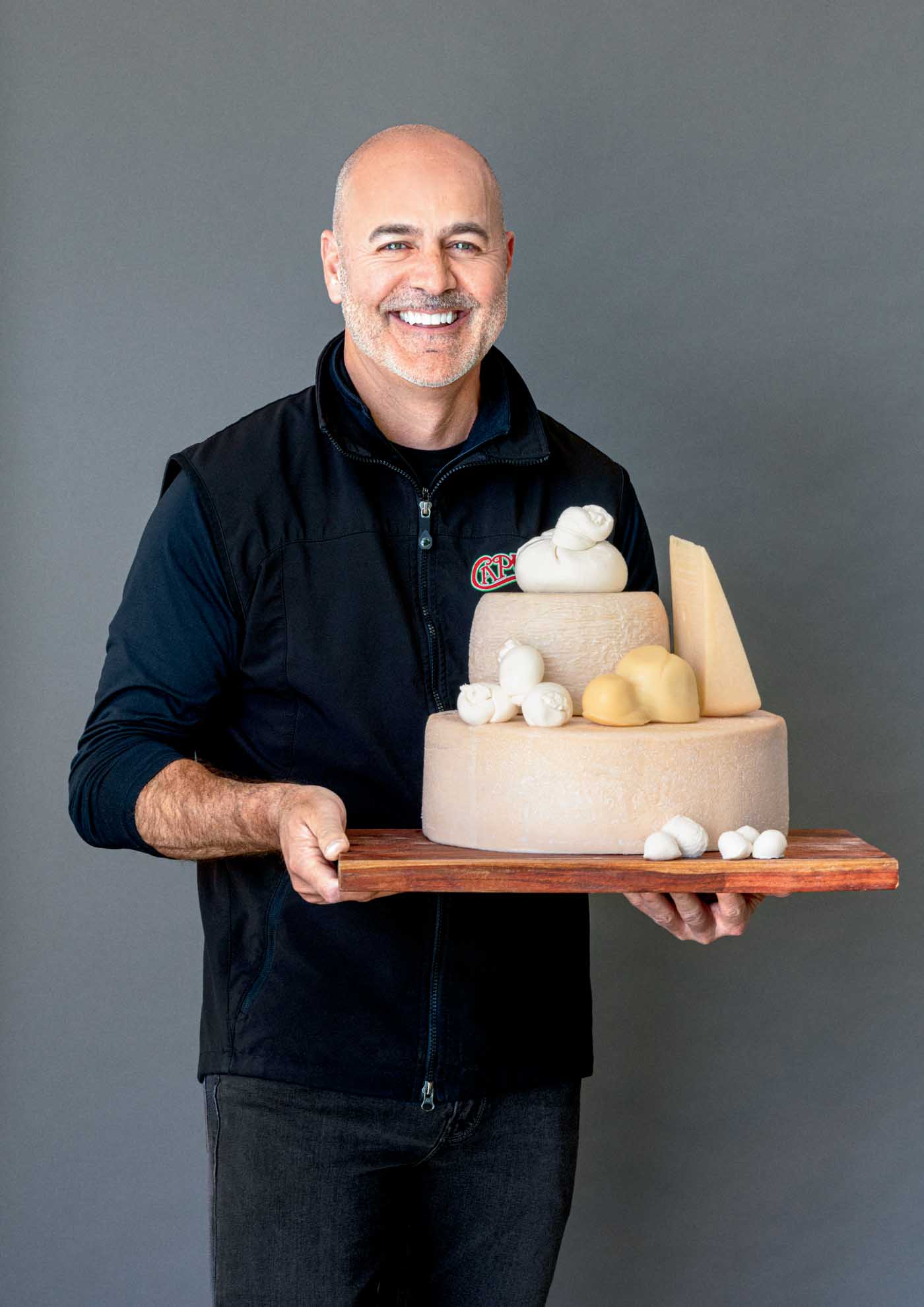

That’s well over five million pounds of fresh mozzarella a year, a number that may grow even more this year with a boost from Caputo’s first place award in the 2024 World Championship Cheese Contest for its fresh mozzarella Nodini (“little knots”).

Stepping into the warmth of the production room, Caputo explains the cheesemaking process and we watch as a worker deftly knots each of the Nodini by hand. But beyond Nodini, there are many other versions of Caputo fresh mozzarella, (each named for shape and size,) plus burrata and ricotta. Perlini are little pearl sized morsels, Cigliegini, are cherry-tomato sized, Bocconcini, bite sized, and so forth.

All are fresh fior di latte (cow’s milk) mozzarella, from the same Caputo recipe— cooked and stretched from mozzarella curd. There are specific nuances to each cut, however, causing each to function differently in a prepared dish. The Nodini, for example, are made with an extra stretching step which gives them a different mouth feel and texture than a traditional 1-ounce ball. And the way the Orecchiette is cut lends best melting properties on a pizza.

Caputo Cheese started making fresh mozzarella in 1996, after then-recent Loyola graduate Caputo returned from time in Italy.

“There, fresh mozzarella was everywhere. People bought it to eat every day. But here, people were mostly familiar with low-moisture, part skim mozzarella, which is a very different thing. I wanted to change that.”

To ensure best possible quality, Caputo purchased the production equipment in Italy where he trained in fresh mozzarella making.

“And then the equipment team sent their experts from Italy here, to make sure we really had the processes down,” he says. “The division started as a crazy idea that obviously worked out and is a major arm of our company today.”

But Caputo’s cheese exploits started when he was a boy following in the footsteps of his father, Pasquale, who founded Caputo Cheese 1978.

“When I was 10, my father taught me how to run the cash register,” says Natale. “By 14, I was cutting and wrapping cheese. At 16, I was slicing cheese in our deli. And at 18, I drove the delivery truck.”

Pasquale also started young, emigrating from Bari, Italy in 1954, when he was just 11. Like most who came to the States back then, Pasquale passed through Ellis Island and briefly stayed in New York City and Brooklyn before coming to Chicago where most of his family was already established.

Finding his footing after vocational high school, Pasquale worked for several of his brothers—Frank, who owned a chain of McDonald’s in the Boston area, and Angelo and Joe, who were in the grocery business in Chicago. Wanting to blaze his own trails, Pasquale opened a hamburger restaurant called Henry’s, and then, several namesake pizzerias. Missing the best quality foods from Italy he knew and loved, Pasquale incorporated Pasquale Caputo Foods in 1978 and began importing Pecorino Romano, Parmigiano Reggiano, and Mozzarella di Bufala cheese, extra virgin olive oil, pasta, spices, and other Italian specialties.

And then came his bright idea—delivering to a restaurant. Pasquale saw that its tomatoes and buns came in pre-sliced, the lettuce, pre-shredded. He remembered that he, too, always pre-shredded the mozzarella he used each day when in the pizza business. Believing there was a need for this kind of high-volume industry prep, he opened a cheese shop in Chicago in 1979 selling retail cheeses at the front and processing larger packages of grated and shredded cheese for wholesale use at the back.

His hunch was right. Demand for the processed product grew, and the company expanded to three stores in Chicago plus a 5,000-square-foot cheese processing facility. By 1990, demand for its wholesale product was so great, Caputo sold off the stores, and moved to a 50,000-square-foot facility in suburban Melrose Park—now expanded to 200,000 square feet.

To ready its products, Caputo brings in cheeses from all over the world and then ages, grates, shreds, mixes, blends, and repackages them for sale to food manufacturers, distributors, and restaurant chains.

Keeping on top of it all is challenging, as the scenario for imports constantly shifts due to worldwide trade, agricultural, and monetary issues.

“As trade agreements change, so do the imports. As the dairy industry changes domestically and abroad, so do imports. As the value of our dollar changes, so do the imports,” says Caputo.

Currently, with a strong dollar, available capacity, and strong consumer consumption, most of Caputo’s supply is domestic. But certain products are always imported: Pecorino Romano and Parmigiano Reggiano from Italy, Manchego from Spain, Feta from Greece, and blue cheese from Denmark.

Meanwhile, all fresh mozzarella, Burrata, and Ricotta offerings are made in house. The Burrata is perhaps Caputo’s most luxurious product. The outer shell is cooked and stretched fresh mozzarella. But inside, Stracciatella—stretched bits and pieces of fresh mozzarella— are combined with cream and milkfat. Rounded and top-knotted into a softball-sized pillow, the result is decadence on a plate.

Innovation is always on the table. Caputo’s yet-to-market Elevated Cow, a CBD-infused fresh mozzarella, is a great example.

Spearheading research and development of the product for more than a year, Caputo says he made batch after batch until he got the recipe exactly right.

“In the end, we manufactured a perfect product with the positive qualities CBD had to offer only to be shut down by the Illinois Department of Health and the FDA,” he says. “It seems that there is a small loophole with regards to CBD/Hemp and food. It is not yet legal to produce any food labeled ‘containing CBD’. Most items you see on the shelf today that claim CBD are actually made with hemp.”

While Elevated Cow awaits changes in law to allow for distribution, Caputo Cheese has other ideas percolating— an imported line of fresh Mozzarella di Bufala to complement its fresh mozzarellas for example.

And beyond that?

“Well, I can’t really discuss those things without alarming my competitors,” Caputo laughs. “But I will say that we are a solutions provider, and we are constantly asked for many variations of our award-winning cheese. So, there are tasteful things coming. Stay tuned!”

Sign Up for the JWC Media Email